Caring for Industrial Air Compressors

Air compressors come in all kinds of sizes and applications. They could be used for bike pumping, auto repair, or larger, industrial jobs, just to name a few. That’s why it’s important to keep these air compressors maintained. If air compressors aren’t cared for, then they could be damaged and last a short time. Here are some maintenance tips that will keep your residential or industrial air compressor running efficiently.

Reduce Air Leaks

Holes in your industrial air compressors can make them work much harder. It causes the required pressure to fluctuate. You may have to replace your hoses if this is the case. Much of the time, you’ll be able to hear the leaks if you check regularly during non-production times. However, there are those leaks you can’t see or hear. This is where an ultrasonic leak detector can come in handy. Use this for regular maintenance on your air compressors to find these leaks so you can fix them as soon as possible.

In addition, try to prevent air leaks. This is done by timely cleaning the pipes of any dirt or dust. The pipes of air compressors must be clean and dry. There can’t be any clogs, as that can cause contamination or corrosion. This, in turn, leads to holes.

Lubricate Regularly

To help keep the gears running smoothly and efficiently, you’ll need to lubricate them. There’s no need to take the device apart, however. This includes larger air compressors for industrial use. To lubricate air compressors for industrial use, you would need a pneumatic lubricator. The aerosolized oil can be applied to the inside of the pipes and lead to the inner workings of the device, this includes the engine and seal. Be sure to lubricate every other month so the compressor can work more efficiently for a longer period of time.

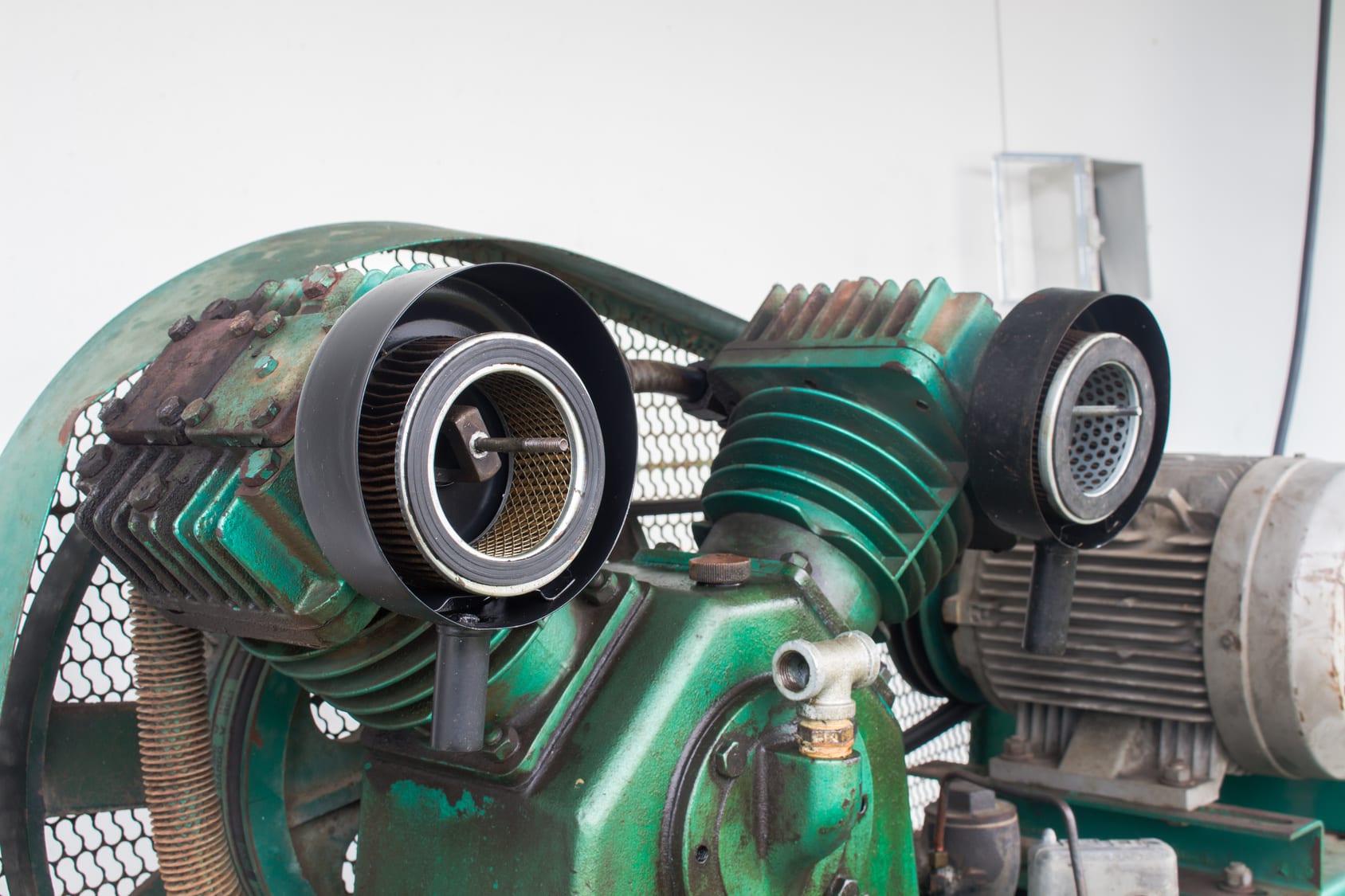

Change Filters Regularly

You want your industrial air compressors to pump clean air. To help keep it consistently clean, you’ll need to change the filters regularly. If you don’t change your filters, then this can result in pressure drops. Pressure drops lead to more energy being used and, in turn, more money being spent.

All air compressors for industrial use need to undergo maintenance to last longer and more efficiently. Fixing air leaks, lubrication, and changing filters are just three of multiple ways to care for your air compressors. Check your compressor’s manual or contact the manufacturer on details about how to maintain your particular industrial air compressors.

Air Power Equipment Company in Oklahoma City (OKC), is the leading source for new air compressor sales and used air compressor sales throughout the country. We specialize in rotary screw air compressor sales and reciprocal air compressor sales. Air Power Equipment Company is also the best source for air compressor service and air compressor parts in Oklahoma.