An Industrial Air compressor is one of the most important things you have to consider in any industry you are working in. For example, air compressors suck in air, decrease its volume, and give it high pressure. The compressed air then moves to a storage tank or is released for different applications like providing air-fueled power to tools like cleaning systems and machinery.

| Contents |

|---|

What Are The Types Of Air Compressors Used In Industry?

Industrial air compressors are essential equipment in construction, mining, agriculture, and manufacturing. When buying an air compressor, you have to ensure that it is energy efficient, high quality, and has high pressure.

Different brands in the market sell different types of industrial air compressors. However, the main categories of air compressors you can choose from are:

Rotary screw

These are the most common types of air compressors in the market. They generate energy using two internal rotors that rotate in opposite directions. As a result, the air gets trapped between the two rotors, building up pressure within the air compressor’s housing.

In most designs of these air compressors, the rotors operate in an oil bath. That helps reduce wear and tear and also ensures a good seal.

You can choose a single-stage or two-stage air compressor. The single-stage rotary air compressors have one set of rotors in one stator housing. The two-stage air compressor has two sets of coordinated rotors in either a standard stator housing or separate stator housings.

These are some of the most accessible air compressors to maintain because they come with an internal cooling system. The cooling system makes it perfect for continuous use.

Rotary screw air compressors produce the most airflow per horsepower compared to other air compressors. However, they come in different power ranges, from 5-350 horsepower. Smaller air compressors are usually belt-driven, while the bigger and more powerful ones are direct-driven.

Rotary screw air compressors can run at 100% duty cycle, and they operate quieter than other types of air compressors. You can either lubricate these air compressors with oil or have them running oil-free.

Pros

- Require low maintenance

- Operate quietly

- Have a high airflow

- You can operate them continuously

- Low initial cost

- They are compact and lightweight

- High volumetric efficiency

Cons

- Not flexible in terms of compression ratio and capacity

- Low discharge pressure per stage

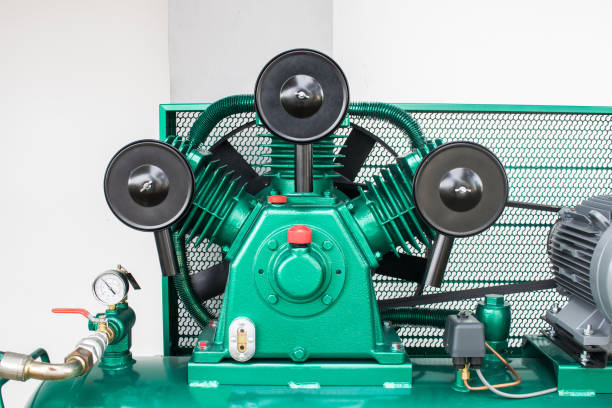

Reciprocating

These types of air compressors operate through a piston found inside a cylinder. The piston is the one that compresses and displaces air, building pressure within the housing. As the piston moves down, it sucks in air, prompting the intake valve to close.

As the piston moves back up, it compresses the air and builds pressure. Because of that, the air released by this type of air compressor has pulses in the pressure, which could result in variable speed and performance issues.

To help deal with that problem, the air produced by this type of air compressor is distributed from a reservoir. Unlike rotary screw air compressors, these are compressors designed to work in smaller sites, and they are not meant to work continuously.

They have more moving parts than rotary crew air compressors, and all these parts are oil lubricated for better movement. This means that reciprocating air compressors need more maintenance and are louder than rotary screw air compressors.

Reciprocating compressors come in single-stage or multi-stage air compressors, determining the pressure you will get. If you want more significant power, the multi-stage air compressors are better than the single-phase models.

They are perfect for intense projects like auto assembly. They can produce up to 30 horsepower. On the other hand, single-stage compressors are perfect for small projects like metalworking and woodworking.

Pros

- You can choose either an oil-lubricated or oil-free variety

- Produces high pressure

- More energy efficient

Cons

- Only perfect for small projects

- They do not run continuously

- They cannot self-regulate capacity against provided output pressure

- High operation noise and vibration

- They require more maintenance

Axial

Axial air compressors have a similar design to jet engines. They draw in the air using fan blades, after which successive blade rings compress it. This design makes them produce high amounts of compressed air, but it is only suitable for high-volume industrial applications.

They are more significant than most other industrial air compressors and more expensive, so they are hardly used in construction projects.

Pros

- Have high-speed capability and efficiency

Cons

- High initial and running cost

- It has a narrow application range

- Its components are more delicate than other types of air compressors

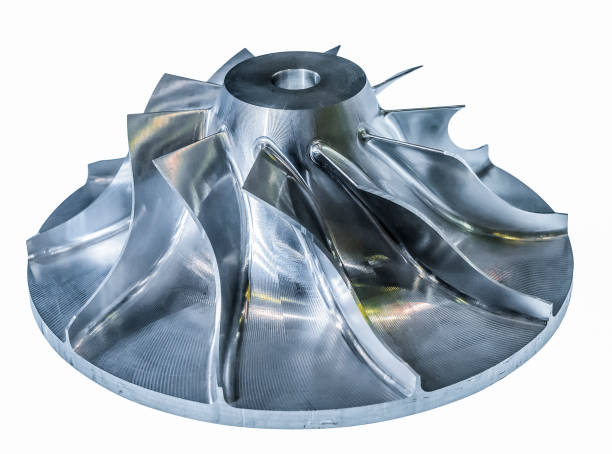

Centrifugal

These air compressors use a ring of rotating fan blades to suck in air and funnel it through the unit at 90 degrees. The air is compressed as it leaves the housing around the blades.

The design of these air compressors makes them produce more compressed air in a small space, making them perfect for high-volume industrial applications like steel manufacturing. These compressors can reach up to 1,000 horsepower.

However, they cannot handle fluctuating air demands. They are also more expensive and require more maintenance than other air compressors.

Pros

- Suitable for producing continuous compressed air

- Generates high-pressure ratio

- High flow rate

Cons

- Have limited pressure

- Sensitive to gas composition changes

How Do I Know What Size Industrial Air Compressor To Buy?

Choosing the wrong sized compressor could lead to operational issues and power waste. You need to ensure that your compressor is the right size, and you also need to consider the tank size to store the right amount of air. Some of the things you need to consider to know the perfect air compressor size you need include:

- What you need the air for.

- The amount of pressure you need.

- Your duty cycle means the amount of time your compressor needs to give consistent high pressure and airflow.

How To Care For My Industrial Air Compressor

Taking good care of your compressor ensures that you always have the proper pressure and last long. Some of the things to do to care for your air compressor properly include:

- Tighten the bolts and nuts

- Clean intake valves

- Change the air filter often

- Inspect the hoses regularly

- Drain condensate from the compressor tanks

- Clean the fuel tank

- Change the air/oil separator

- Change the oil often

Where Can I Buy An Industrial Air Compressor?

Where you choose to buy your compressor will determine the quality and performance of your air compressor. Air Power Equipment Co. is the best place to shop for high-quality industrial air compressors in Oklahoma.

Different types and sizes of air compressors are designed to fit your industrial needs. Having been in the market for over four decades, you are guaranteed the best service and products. You also get a warranty for all the products you purchase. For Air Compressor Safety comply with OSHA regulations.

Air Power Equipment Company in Oklahoma City (OKC), is the leading source for new air compressor sales and used air compressor sales throughout the country. We specialize in rotary screw air compressor sales and reciprocal air compressor sales. Air Power Equipment Company is also the best source for air compressor service and air compressor parts in Oklahoma. If you are looking for new air compressors, used air compressors, air compressor parts, or air compressor service call Air Power Equipment Company OKC. We are experts with all brands of air compressor equipment and we are a stocking distributor of air compressor brands like FS Curtis Air Compressors, Champion Air Compressors, Campbell Hausfeld Air Compressors, Kellogg Air Compressors, American Air Compressors, Quincy Compressor and many more. Call us at (405) 445-1216 – we have what you need, and at the best price you will find.