Do you have an air compressor that isn’t turning on? Are you wondering what you should do? You might consider giving up, but there are a few things that you can try before throwing in the towel and calling for professional help. If your air compressor doesn’t seem to be getting any power, make sure it’s plugged into an outlet with power and check if it has blown a circuit breaker or tripped a GFCI breaker. If none of these items seem to apply, then chances are your motor burned out.

| Contents |

|---|

How Do You Reset An Air Compressor?

Air compressors are used to power tools such as nail guns and spray paint. They are often in use for long periods, which can cause them to overheat if not turned off correctly. If you find that your air compressor isn’t turning on, the compressor motor is overheating, or isn’t keeping up with the job; it may be time for a reset.

Resetting an air compressor is a quick and relatively easy task that will allow the unit to cool down before getting back into action. However, it’s important to note that compressors aren’t designed for continuous use and should not run longer than they need to complete your project.

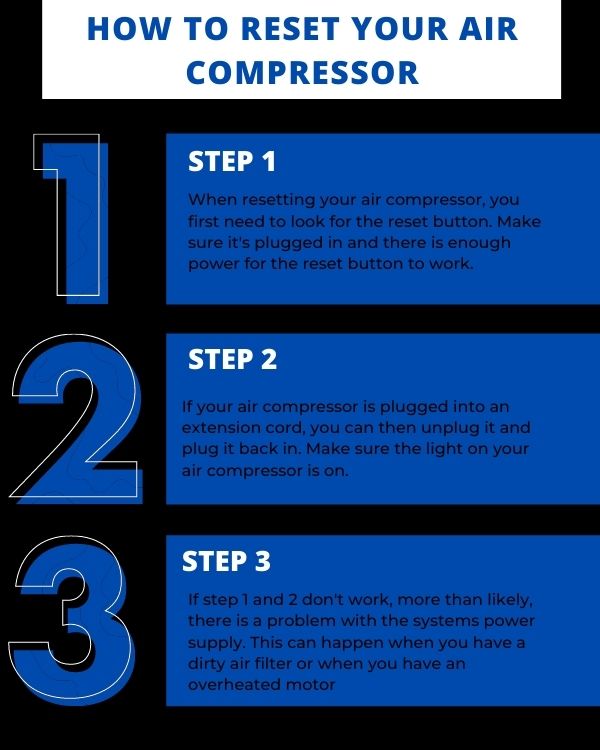

To reset an air compressor, you need to follow a few simple steps.

- First, you need to find the reset button on your air compressor. If there is no power going to it when it shuts off, you will need to plug it in to allow it to run until the power shuts off. When you hear the compressor start back up, push the reset button. The power light on your air compressor will go out. You can then turn it back on, and you should reset the system.

- If you are using an air compressor powered by an extension cord, you can unplug and plug it back in to reset the connection. This process will also work if the power light on your compressor is not going out when you push the reset button.

- If neither of these resolutions works, the problem is most likely with your system’s power supply. The cause of this problem is a dirty air filter, which you will need to replace if this is the case. Additionally, an overheated motor can be a problem, and you should replace it.

How Do You Fix An Air Compressor That Won’t Start?

If you have a small project that requires an air compressor, the chances are that the first step is to check if it’s turned on. If there isn’t a power switch or a button available to turn on your machine, it may mean something is wrong with its electrical system, and you should check this before anything else. On the other hand, when you turn on the machine, it’s time to check if any loose connections or faulty air power equipment parts may prevent your air compressor from working.

You should check to make sure that it is receiving power. If not, you will need to repair or replace the compressor’s electrical wiring and the circuit breaker. If it is receiving power, then check to see if there are any loose wires or connections. This problem may be a sign of a bad starter switch or a blown fuse. If there are no issues with the compressor’s electrical components, then it is likely that you will need to replace the starter switch.

Different issues will require different fixations; the main thing is determining the root cause of the issue. For example, if you lack air pressure or power, your motor coil likely needs to be replaced. The compressor itself may also need replacing if there are issues with the tank and valves; however, these can sometimes require high levels of expertise.

Before investigating any further problems, turn off the machine before checking for leaks and discharging any pressure remaining in the tank. Your local hardware store will be able to provide you with information on any further requirements needed for your compressor, such as air compressor replacement parts or repairs that are outside of your capabilities.

[5 Things to Do With an Old Air Compressor]

What Is The Most Common Cause Of An Air Compressor Not Turning On?

The common cause of an air compressor not working is a drain valve not being closed. If the drain valve is left open, compressed air will flow out of it instead of into the tank, which causes the compressor to shut off. You may resolve this by checking for a clog in the line or opening and closing the drain valve until it starts to work.

The common cause of an air compressor not working is a drain valve not being closed. If the drain valve is left open, compressed air will flow out of it instead of into the tank, which causes the compressor to shut off. You may resolve this by checking for a clog in the line or opening and closing the drain valve until it starts to work.

Another common cause of an air compressor not turning on is a blown-fuse or tripped circuit breaker. Resolve this by checking the circuit breaker to ensure it is not tripped and by checking the fuse box.

Sometimes, an air compressor will stop working due to its overheating: ensuring that the compressor has proper ventilation and is not in an enclosed space.

Another potential cause of an air compressor not turning on is a power outage. Fix this by checking the circuit breaker to ensure it is on and working correctly and checking the fuse box.

An air compressor may also not turn on if it is out of oil or has low oil levels. Resolve this by adding oil and taking the air compressor in for service to ensure no internal damage.

What Is The Condition Of Your Air Compressor?

Most people are guilty of not being up to date with the condition of their air compressor. You should be checking your air compressor at least three times a year to ensure that everything is working correctly. If you go too long without checking on the condition of your air compressor, you could be facing some pretty big problems.

You must invest in a high-quality air compressor to avoid doing too much maintenance. The first thing you should check is the click sound that your compressor makes, which will indicate if it has gone wrong. If you notice that your click sound is not as loud, it’s time to check the tank pressure, which can be done by simply reading the tank pressure gauge. The tank pressure should remain between 100 and 125 lbs to ensure that you are getting good airflow.

The starting capacitors will typically need replacement every five years. You must check for any loose wires or motor mounts to ensure the motor stays secure in place. You will need to test the motor every year to determine if it is still running well or needs replacement. Take note of when the motor starts if there is any unusual sound coming from it.

The location of the uploader valve or pressure valve is on or near the compressor pump. The unloader’s job is to reduce the high-pressure (up to 150 PSI) air coming from the tank. The unloader valve has a small pilot line to an “oil separator,” a collection of baffles that separate oil from the air. Keeping the separator clean is essential because it can cause the compressor’s motor to run dry if it gets clogged.

Bear in mind that compressed air systems are very complex and require a trained professional to work on them. Therefore, if you notice problems with your air compressor, be sure to contact an experienced technician for service.