Choose the Best Compressor for your Venture

Some of the essential equipment you can find at any construction project are air compressors. Nevertheless, the usage of air compressors is not just narrowed to construction projects. They can also be used in airplanes, ships, chemical, and manufacturing plants. The central purpose of an air compressor is to transform a source of power into stored energy.

There are various types of air compressors, and each comes with their unique capabilities and shortcomings. They can be categorized based on so many factors, and one of them is their principle of operation; positive displacement or dynamic displacement. The dynamic compressor produces horsepower by taking in air with fast rotating blades then containing the air to create pressure. These compressors then store the kinetic energy produced as static energy. A positive displacement compressor creates energy through air displacement. A fissure inside the instrument stores the air from outside then gradually compresses the fissure to increase the potential and pressure of air.

AirPower Equipment is a family company that deals with the sale and repair of air compressors and any other equipment related to an air compressor for over 40 years. Since Air Power Equipment is a leading company in the sale of air compressors, it offers you the best product at a pocket-friendly price.

What are the Different Types of Air Compressors?

1. Rotary screw Air Compressors

It is a type of displacement Compressor with a power range of 5 horsepower up to 350 horsepower. It is effortless to maintain and take care of as the compressor comes with an internal coolant, and it has an individual filter. The rotary screw compressor usually is significant, and it can operate oil-free or be lubricated using oil. The rotary screw compressor comes designed with two rotors that rotate in different directions, thus producing energy. Air gets trapped in between the rotors; therefore, the pressure is created. The rotary screw compressor can continuously work since it has its internal coolant. Some of the brands that AirPower equipment sales are; Champion Rotary Screw Air Compressor and FS Curtis Rotary Screw Compressors.

2. Reciprocating Air Compressor

2. Reciprocating Air Compressor

A reciprocating compressor is another kind of displacement compressor. It usually is a small-size machine; hence you can mostly use it at small work sites like home construction or a garage. Unlike a rotary screw air compressor, a reciprocating air compressor is not designed to work continuously. It has more moving parts as compared to a rotary screw air compressor, so for it to work smoothly, always ensure that these parts are lubricated using oil. This means that this kind of air compressor requires a constant inspection for it to last longer.

It has a piston inside a cylinder that compresses and dislocates air to produce pressure. Reciprocating air compressor usually comes in two kinds; either single or multi-stage variation. A single-stage compressor is most appropriate for smaller jobs like woodwork and metalwork. In contrast, a multiple-stage compressor can be used for more heavy-duty construction like auto-assembly since it produces more energy.

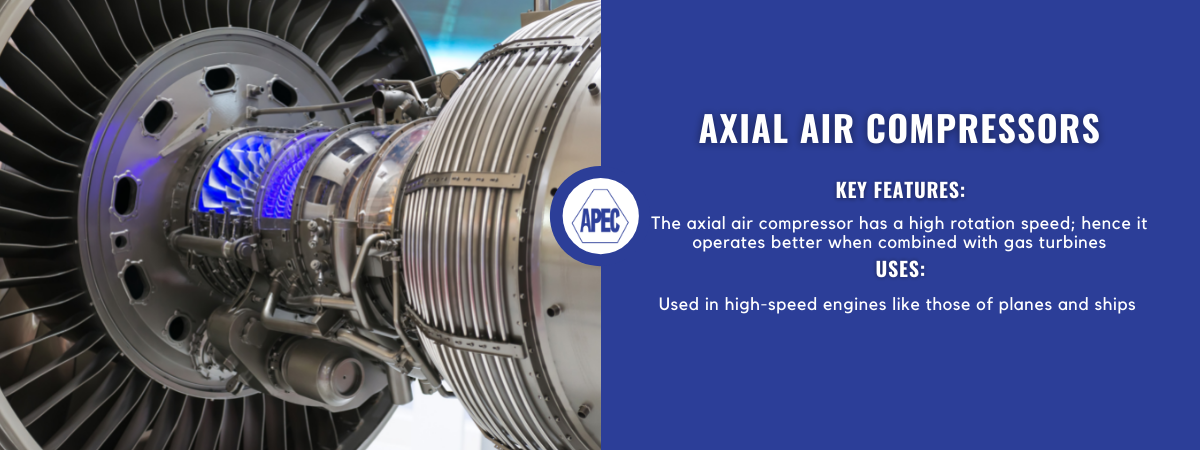

3. Axial Air Compressor

3. Axial Air Compressor

It is the most expensive type of air compressor since it has a high-efficiency rate. The axial compressor has fixed blades where air passes to create kinetic energy, which is later converted into pressure. The axial air compressor has a high rotation speed; hence it operates better when combined with gas turbines.

This compressor is not used in any construction project; instead, it is used in high-speed engines like those of planes and ships. It is also reserved for aerospace exploration since it can create up to thousands of horsepower.

4. Centrifugal Air Compressor

4. Centrifugal Air Compressor

Centrifugal air compressor relies on energy transmitted from the spinning impeller disk to the air. The impeller has blades that rotate powerfully inside the disc. These steady rotations help the air inside the cylinder to gain velocity. A diffuser then transforms the energy created into static energy. Centrifugal compressor does not need constant maintenance since they do not have valves; thus, the only thing you need to do is inspect the bearing just in case they wear out regularly. There are two types of centrifugal compressors single-stage or multi-stage compressors. Single-stage has only one impeller while a multiple-stage compressor has 1 to 10 impellers.

Although the centrifugal air compressor is a small machine, it has a multi-phase compression process that produces a high energy amount. Some centrifugal air compressors can produce oil-free air, and this makes it very easy to maintain and take care of than even the rotary screw air compressor. Centrifugal compressor is mostly used in construction projects that require a lot of energy, such as steel manufacturing or chemical manufacturing, as it can produce almost up to 1000 horsepower.

When buying an air compressor, always ensure you purchase the one that will efficiently meet your needs. And with all this information provided, you are in a better position to make a wise decision.

When buying an air compressor, always ensure you purchase the one that will efficiently meet your needs. And with all this information provided, you are in a better position to make a wise decision.

Air Power Equipment Company in Oklahoma City (OKC), is the leading source for new air compressor sales and used air compressor sales throughout the country. We specialize in rotary screw air compressor sales and reciprocal air compressor sales but have any types of air compressors you are looking for. Air Power Equipment Company is also the best source for air compressor service and air compressor parts in Oklahoma. If you are looking for new air compressors, used air compressors, air compressor parts, or air compressor service call Air Power Equipment Company OKC. We are experts with all brands of air compressor equipment and we are a stocking distributor of air compressor brands like FS Curtis Air Compressors, Champion Air Compressors, Campbell Hausfeld Air Compressors, Kellogg Air Compressors, American Air Compressors, Quincy Compressor, and many more. Call us at (405) 445-1216 – we have what you need, and at the best price you will find.