Power up with Diesel Air Compressors.

Air compressors that run on diesel have no equal in terms of mobility, power, and autonomy when no power source is available as electricity. Both in remote terrain operation, a job site or a high-demand industrial application, our diesel air compressors have the reliability to supply the compressed air anywhere you need it.

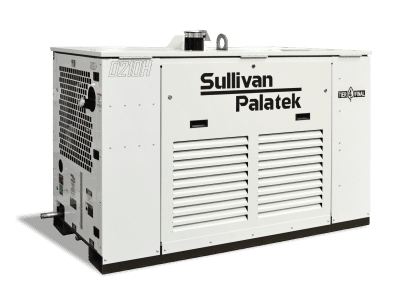

Diesel Air Compressors

Choosing the Right Diesel Air Compressor.

The ideal diesel air compressor that fits you will be dependent on your use necessities, the application necessities, and power.

The points of consideration are:

- Free Air Delivery (CFM): Be certain that the diesel air compressor has the capacity to supply your peak air requirement of your tools and processes.

- Working Pressure (PSI/Bar): The majority of the applications are done with a pressure of about 100 PSI (approximately 7 bar), yet more strenuous tasks might expect a pressure of over 150 PSI to run a diesel engine air compressor.

- Mobility & Mounting: Decide whether the diesel air compressor should be trailer towable, skid mount or vertically or horizontally mounted. Ensure that the unit can be transported with less effort when utilizing on an uneven surface particularly when using a Quincy Compressor diesel air compressor. If you want to explore some different air compressors at a reasonable price you can check here.

- Engine and Cooling: Since the diesel engine should be able to resist the ambient and dust and be used for a lot longer periods it is all promoted to be cooled effectively or filtration solutions are highly encouraged to be heavy-duty.

- Duty Cycle & Runtime: Some applications require the engine to run continuously varying loads of power, so make sure to select a diesel powered diesel air compressor that’s built for long duty cycles, and that will not impact your job site downtime.

- Environment & Fuel Access: Some sites may be remote, and will either not have access to fuel or will get colder, or the air compressor will be put into field conditions that put either the power unit or diesel air compressor into a challenging location for engineers to plumb your compressor.

- Service & Spares: Diesel engines must be serviced regularly, so check on parts availability for a diesel air compressor for sale, and existing service network, before jumping into a decision to purchase.

Applications (Examples):

Diesel air compressors are regularly applied in:

- Repairs and excavation (excavators, jackhammers, road works).

- Mining and quarrying (drilling in rocks, explosions)

- Oil and gas (pigging, remote drilling rigs, etc.)

- Rental fleets and mobile businesses where there is no electric power, or power is inadequate.

FAQs

Service & Support

Your diesel air compressor is designed to work under very hard conditions-and it should be properly maintained by an expert to ensure that it works at its full capacity. Our support division offers services at every level including the professional installation and scheduled maintenance of equipment, as well as on-site repairs within a short period of time. All technicians have been trained in the factories to diagnose mechanical and engine related problems in the shortest possible time ensuring that your system is back to full efficiency taking minimal time. We have a stock of authentic parts and accessories such as filters, belts, hose and lubricants- so that replacements are done within a short time and with the first time. We have comprehensive service programs, which involve fuel efficiency inspection, air quality inspection, and prevention checks, which contribute to the increased compressor life and lowered operating expenses. We can offer the support of reliability, technical know-how and technical skills when operating a towable unit in a distant location or have a skid-mounted system that can be used to feed the industry. All the normal maintenance plans and stand-by emergency services, our employees will strive to ensure that your diesel compressors are in good condition, safely and economically- no matter the source of the assignment.