| Weight | 630 lbs |

|---|---|

| Horsepower | 7.5 |

| CFM | 22.3CFM AT 175PSI |

| PSI Configuration | 175 |

| Pump Type | Two Stage |

| Phase Configuration | 1, 3 |

| Voltage | 200, 230, 460 |

| Tank Size | 80 |

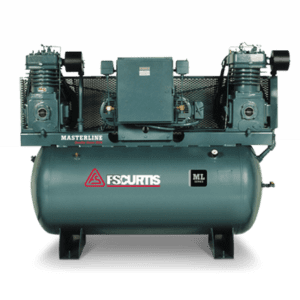

Champion HR7F-8, 7.5HP Two-Stage 80-Gallon Horizontal Air Compressor Unit

Free Freight!

*PLEASE NOTE DUE TO THE EXTENUATING CIRCUMSTANCES LEAD TIME IS UP TO 4-6 WEEKS. PLEASE CALL FOR DETAILS.

Champion R-Series Compressor pumps have a time-tested, proven design. Rugged standard features, a wide selection of configurations, and quality available options make the R-Series compressors the solution to your application. Delivering high performance, long life and tremendous value. Champion compressors are the proven choice!

- USA Made

- Disc Valves

- Rated at 22.3 CFM at 175 PSI, 175 PSI Max

- 949 Pump RPM

- Motor Starter Included

- 3-Year Limited Warranty

- 630 lbs

- L– 66.5’’ W– 23.25’’ H– 52’’

Your Price:

$3,845.00

- Pictures shown are for illustration purposes only. Actual product may vary due to product specifications.

- All prices on this website are subject to change without notice. Whilst we make every effort to provide you with the most accurate, up-to-date information, occasionally, one or more items on our website may be mis-priced. In the event a product is listed at an incorrect price due to typographical, photographic, or technical error or error in pricing information received from our manufacturers, Air Power Equipment Co. shall have the right to refuse or cancel any orders placed for product listed at the incorrect price.

Loaded with rugged features, the R-Series splash-lubricated compressors deliver high performance, long life and tremendous value.

1 Multi-finned cylinders

Cooler operating temperatures result in longer life and consistent performance over time.

2 Integral cylinder/head

Gasketless design eliminates the possibility of blown head gaskets for trouble-free operation.

3 Balanced pistons

Aluminum alloy first-stage piston is weight matched to the cast iron second-stage piston, ensuring proper balance.

4 Piston rings

Two compression rings and one oil control ring provide excellent oil control, and high efficiency air delivery.

5 Lightweight connecting rods

High-density, die-cast aluminum alloy rods minimize reciprocating weight. An integral, precision- bored crankpin bearing and a needle bearing for the piston pin properly distribute bearing loads for longer bearing life than bushings.

6 Pressure relief valves

Located in interstage and discharge.

7 Intercoolers

Large-diameter finned tubing is positioned to obtain the greatest cooling effect between stages for maximum compressor efficiency.

8 Optimized cooling fan/flywheel

Precision balanced flywheel has fan blades for optimum compressor cooling and life.

9 Reliable, high-flow valves

Single-unit, disc-type valves provide low lift and long life. Discs are made of corrosion resistant Swedish steel. Valves are easily serviced by removing the manifolds only.

10 Oversized main bearings

Tapered roller-type main bearings provide full contact and support of the crankshaft plus delivers the longest possible life.

11 Balanced crankshafts

Constructed of rugged ductile iron with large diameter throws for minimum bearing loads and counterweights to minimize vibration.

12 Large capacity crankcase

Rugged cast iron oil reservoir has convenient sight gauge glass, corner oil fill boss and large oil drain.

13 Loadless starting

Positive acting, governor-type centrifugal unloader assures longer motor life by allowing the compressor to start unloaded every time.

| Weight | 630 lbs |

|---|---|

| Horsepower | 7.5 |

| CFM | 22.3CFM AT 175PSI |

| PSI Configuration | 175 |

| Pump Type | Two Stage |

| Phase Configuration | 1, 3 |

| Voltage | 200, 230, 460 |

| Tank Size | 80 |

Loaded with rugged features, the R-Series splash-lubricated compressors deliver high performance, long life and tremendous value.

1 Multi-finned cylinders

Cooler operating temperatures result in longer life and consistent performance over time.

2 Integral cylinder/head

Gasketless design eliminates the possibility of blown head gaskets for trouble-free operation.

3 Balanced pistons

Aluminum alloy first-stage piston is weight matched to the cast iron second-stage piston, ensuring proper balance.

4 Piston rings

Two compression rings and one oil control ring provide excellent oil control, and high efficiency air delivery.

5 Lightweight connecting rods

High-density, die-cast aluminum alloy rods minimize reciprocating weight. An integral, precision- bored crankpin bearing and a needle bearing for the piston pin properly distribute bearing loads for longer bearing life than bushings.

6 Pressure relief valves

Located in interstage and discharge.

7 Intercoolers

Large-diameter finned tubing is positioned to obtain the greatest cooling effect between stages for maximum compressor efficiency.

8 Optimized cooling fan/flywheel

Precision balanced flywheel has fan blades for optimum compressor cooling and life.

9 Reliable, high-flow valves

Single-unit, disc-type valves provide low lift and long life. Discs are made of corrosion resistant Swedish steel. Valves are easily serviced by removing the manifolds only.

10 Oversized main bearings

Tapered roller-type main bearings provide full contact and support of the crankshaft plus delivers the longest possible life.

11 Balanced crankshafts

Constructed of rugged ductile iron with large diameter throws for minimum bearing loads and counterweights to minimize vibration.

12 Large capacity crankcase

Rugged cast iron oil reservoir has convenient sight gauge glass, corner oil fill boss and large oil drain.

13 Loadless starting

Positive acting, governor-type centrifugal unloader assures longer motor life by allowing the compressor to start unloaded every time.