How to Choose the Right Industrial Air Compressor: A Guide by Air Power Equipment

- 01 Understand Your Air Demand: Flow (CFM) & Pressure (PSI)

- 02 Choose Your Industrial Air Compressor Type Based on Usage

- 03 Efficiency & Energy Cost Over the Life of an Industrial Air Compressor

- 04 Reliability, Maintenance & Support

- 05 Noise, Footprint Installation Considerations

- 06 Upfront Cost vs Total Cost of Ownership

- 07 Environmental & Safety Considerations

- 08 Matching to Your Budget & Operations

- 09 Why Air Power Equipment Is Your Partner in Choosing The Right Equipment

- 10 Industrial Air Compressor Summary

- 11 Air Power Equipment

Choosing the right industrial air compressor is more than just picking a familiar brand or the biggest horsepower you can afford. The right compressor optimizes your operations, saves energy, reduces downtime, and lasts longer. At Air Power Equipment (OKC Air Compressors), we’ve helped customers in Oklahoma and beyond select compressors that match their actual needs and not just their wish lists. Here’s what to consider when specifying an industrial air compressor to ensure a smart investment.

Understand Your Air Demand: Flow (CFM) & Pressure (PSI)

The first step is to determine your required air flow (measured in CFM: cubic feet per minute) and air pressure (PSI).

- Flow (CFM): What tools, machines, or processes will you power simultaneously? Add up their air consumption. If you undersize the flow, you’ll face bottlenecks; if you oversize, you waste money on equipment you don’t need.

- Pressure (PSI): Different tools require different pressures. For example, pneumatic tools may require 90-PSI, while spray booths may demand higher pressures. Be sure to note both the required working pressure and the maximum allowable pressure.

Also, allow for a future expansion plan that accommodates 10-25% more flow than your current needs to cater to growth or unexpected peaks.

Choose Your Industrial Air Compressor Type Based on Usage

Industrial air compressors come in several types. Matching the type to your usage pattern is critical.

- Rotary screw compressors: Excellent for continuous-duty, high-volume applications. Lower noise, smoother operation, and more efficient at higher loads. APEC carries leading rotary screw models.

- Reciprocating (piston) compressors: Better for intermittent duty. Less expensive for lower volumes or occasional use. But they may require more maintenance and be noisier.

- Oil-free vs. oil-lubricated: If compressed air quality is critical (e.g., food processing, pharmaceuticals, electronics), oil-free models are essential. For many industrial applications, oil-lubricated compressors are fine.

At APEC, we also provide gas-powered compressors when electricity is not feasible or when you are operating in remote locations.

Efficiency & Energy Cost Over the Life of an Industrial Air Compressor

An industrial air compressor isn’t just about the purchase. Overall price versus operating costs often dwarfs that. Consider:

- Efficiency rating / Specific power usage: How many kW does it require per CFM delivered? More efficient machines may cost more upfront, but save on utility bills.

- Duty cycle: A “100% duty-cycle” unit can run continuously; if your demand is near continuous, this is a significant consideration.

- Variable speed drives (VSDs) or staging: Help save energy by matching output to demand instead of running at full capacity all the time.

Air Power Equipment offers preventative maintenance plans that help ensure the compressor remains energy-efficient by keeping components clean, performing regular tune-ups, and addressing leaks, among other essential tasks.

Reliability, Maintenance & Support

A compressor that’s down is costing you more than one that’s less efficient but reliable. Key factors:

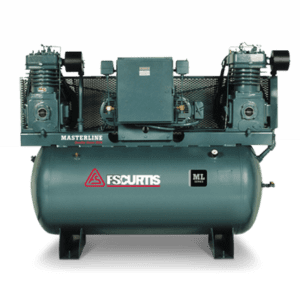

- Quality of parts & build: Brands with good reputations, solid warranties, and good support. APEC carries FS-Curtis, Champion, Jenny, and more.

- Serviceability: Can filters, oil, belts, and other components be serviced easily? Are replacement parts readily available?

- Preventative maintenance: Scheduled maintenance tasks like oil changes and air filter replacements helps extend the unit’s life. It will help prevent major breakdowns. APEC offers preventive maintenance plans for our air compressors.

- On-site service: Being able to receive a technician’s response quickly when something fails, or better yet, avoiding failures through regular maintenance, can save significant amounts of downtime. APEC has on-site repair service.

Noise, Footprint Installation Considerations

Don’t overlook the physical and environmental constraints when choosing a compressor.

- Noise levels: Some rotary screw models are much quieter than reciprocating machines. If the compressor will be located inside or near workspaces, reducing noise is crucial.

- Space/layout: Does it need a large tank? Is it vertical or horizontal? Clearance for ventilation? Can you access maintenance points easily?

- Power supply considerations: It’s important to consider your electrical supply (your voltage and phase) or the on-site availability of gas vs. diesel. Match the compressor to your existing infrastructure to avoid costly electrical/installation upgrades.

Upfront Cost vs Total Cost of Ownership

It’s tempting to compare only the purchase prices, but the total cost over the machine’s life and durability matters most.

- Purchase & Installation Cost: The price includes any freight, installation, wiring, or plumbing modifications.

- Operating cost: Electricity or fuel, maintenance, parts, filter/oil replacements.

- Downtime cost: Lost production when the compressor fails or underperforms.

- Lifetime & resale value: How long will the compressor last under typical use? Brand reputation matters. Well-known brands like Champion or FS Curtis provide value and efficiency that can yield significant savings year after year.

Environmental & Safety Considerations

Industry standards, safety, and environmental impact should also guide your choice.

- Emissions: If using gas-powered units, their emissions are a concern. Also, oil-free versions avoid oil carryover.

- Air quality & air treatment: Aftercoolers, dryers, filters, regulators, etc. Compressed air must be dry and clean for many applications. APEC offers filters, regulators, lubricators, compressed air dryers, and aftercoolers.

- Safety devices: Include Pressure relief valves, check valves, and safety switches. Ensure the compressor includes or allows for easy installation of the required safety equipment.

Matching to Your Budget & Operations

Ultimately, by combining all the above, you’ll arrive at a realistic specification. Here are some tips:

- Prioritize features that matter most in your operation (flow, reliability, maintenance, energy cost).

- Get multiple quotes, compare not only brands but also service and parts availability locally.

- In many cases, it’s better to slightly overspec than underspec (within reason) to allow for expansion or unforeseen added load.

- Consider financing, leasing, or buying used—but only if the used units are in good condition, come with a warranty, or offer local support. At APEC, we focus on quality, new, well-supported models.

Why Air Power Equipment Is Your Partner in Choosing The Right Equipment

At Air Power Equipment Co. (OKC Air Compressors), we don’t just sell compressors—we help you find the right one. Since 1979, our family has been providing Oklahoma City and the rest of the country with industrial air compressor expertise, parts, service, and support.

- Top-Quality Units: We carry top brands, including FS-Curtis, Champion, Jenny, and more.

- Full service: From on‐site repairs to preventative maintenance, we ensure your compressor stays reliable and efficient.

- Expertise: We’ll help you size correctly, choose the right industrial air compressor type, ensure proper installation, and provide all necessary air treatment (dryers, filters, etc.) to protect quality.

Industrial Air Compressor Summary

Choosing the right industrial air compressor involves understanding your specific unit’s needs, including flow, pressure, and duty cycle. You also need to select the proper type, ensuring efficiency, planning for maintenance, and securing local support. When you get those things right, your compressor becomes a dependable asset and not a liability.

If you need help deciding which compressor fits your operation or comparing models, contact Air Power Equipment for expert advice. We’ll help you assess your current air usage, anticipate future growth, and select a system that strikes a balance between performance, cost, and reliability. Your air demand is our family business.

Air Power Equipment

Air Power Equipment

Air Power Equipment Company in Oklahoma City (OKC), is the leading source for new air compressor sales and used air compressor sales throughout the country. We specialize in the sales of rotary screw air compressors and reciprocating air compressors. Air Power Equipment Company is also the premier source for air compressor service and parts in Oklahoma. If you are looking for new air compressors, used air compressors, air compressor parts, or air compressor service, call Air Power Equipment Company OKC. We are experts with all brands of air compressor equipment and we are a stocking distributor of air compressor brands like FS Curtis Air Compressors, Champion Air Compressors, Toledo Tool Air Compressors Campbell Hausfeld Air Compressors, Kellogg Air Compressors, American Air Compressors, Quincy Compressor and many more. Call us at (405) 445-1216 – we have what you need, and at the best price you will find.