| Weight | 600 lbs |

|---|---|

| Dimensions | 39 × 32 × 78 in |

| Horsepower | 7.5 |

| CFM | 28.7 CFM AT 175 PSI |

| PSI Configuration | 175 |

| Voltage | 200, 230, 460 |

| Phase Configuration | 1, 3 |

| Pump Type | Two Stage |

| Tank Size | 80 |

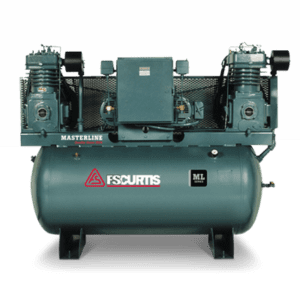

FS-Curtis Masterline ML7.5 7.5HP 80 Gallon Vertical Air Compressor Unit 230v/Single Phase

Free Freight!

Legendary Curtis Masterline Air Compressor Unit 7.5HP

2-Stage, Baldor 7.5HP Premium Efficiency Electric Motor with a 80 Gallon Vertical Tank

5-year limited warranty, Bumper to Bumper

- C-79 True 7.5hp Pump

- Pump RPM -870

- USA Made

- Rated at 28.7 CFM at 175 PSI, 175 PSI Max

- 5-Year Limited Warranty

- Motor Starter

- 82dBA

- 1/2” NPT Outlet

- 600lbs

- L– 36’’ W– 30’’ H– 75’’

*Free freight is drop-shipped from the factory direct to your 48 State Destination. This does not include liftgate service or residential delivery.

Your Price:

$6,563.00

- Pictures shown are for illustration purposes only. Actual product may vary due to product specifications.

- All prices on this website are subject to change without notice. Whilst we make every effort to provide you with the most accurate, up-to-date information, occasionally, one or more items on our website may be mis-priced. In the event a product is listed at an incorrect price due to typographical, photographic, or technical error or error in pricing information received from our manufacturers, Air Power Equipment Co. shall have the right to refuse or cancel any orders placed for product listed at the incorrect price.

Curtis Masterline Air Compressor Unit 7.5HP 2-Stage, Baldor 7.5hp Premium Efficiency Electric Motor with a 80-Gallon Vertical Tank 5-year limited warranty, Bumper to Bumper

- FML07C79V8S-A2L1XX

- Pressure Lubricated

- Pump RPM -870

- USA Made

- Rated at 28.7 CFM at 175 PSI, 175 PSI Max

- 5-Year Limited Warranty

- Motor Starter

- 82dBA

- 1/2” NPT Outlet

- 650bs

- L– 36’’ W– 30’’ H– 75’’

Masterline (ML Series) is the most robust, heavy duty reciprocating air compressor lineup available. The perfect combination of quality components and efficient design make the ML Series rugged, affordable and smart. Because every model is built tough to last a lifetime in demanding working conditions, the ML Series is an outstanding alternative to splash-lubricated reciprocating compressors and small rotary compressors.

1. INTERCOOLER RELIEF VALVE – Prevents excessive pressure in the low pressure cylinder and intercooler, protecting pump and motor.

2. LOADLESS STARTING – With centrifugal, suction valve, or bleeder type unloader.

3. STAINLESS STEEL DISC AND SPRING VALVE ASSEMBLIES – Largest in the industry, ground and lapped to optical flatness for quiet and efficient operation.

4. DEEP FINNED CYLINDERS – Permit better cooling.

5. INTERCOOLER – Extra long with radiating fins located in the cyclone of air from the flywheel, providing maximum heat dissipation.

6. CAST IRON HIGH PRESSURE PISTONS – For durability and long life.

7. BALANCED FLYWHEEL – Provides effective air blast to cool compressor.

8. HEAVY DUTY CAST IRON CONNECTING RODS – Heaviest in the industry with replaceable rod bearings and pin bearings.

9. CAST IRON CRANKCASE – For strength and durability.

10. HEAVY DUTY DUCTILE IRON CRANKSHAFT – Ground and counter balanced with rifle-drilled oil flow ports.

11. OVERSIZED TAPERED MAIN ROLLER BEARINGS – Adjustable to assure long life with less friction.

12. PRESSURE LUBRICATION – With our centro-ring oiling system, pressurized oil is supplied internally through rifle-drilled crankshaft and rods to all bearings, bushings, and wearing surfaces for extended pump life.

| Weight | 600 lbs |

|---|---|

| Dimensions | 39 × 32 × 78 in |

| Horsepower | 7.5 |

| CFM | 28.7 CFM AT 175 PSI |

| PSI Configuration | 175 |

| Voltage | 200, 230, 460 |

| Phase Configuration | 1, 3 |

| Pump Type | Two Stage |

| Tank Size | 80 |

Curtis Masterline Air Compressor Unit 7.5HP 2-Stage, Baldor 7.5hp Premium Efficiency Electric Motor with a 80-Gallon Vertical Tank 5-year limited warranty, Bumper to Bumper

- FML07C79V8S-A2L1XX

- Pressure Lubricated

- Pump RPM -870

- USA Made

- Rated at 28.7 CFM at 175 PSI, 175 PSI Max

- 5-Year Limited Warranty

- Motor Starter

- 82dBA

- 1/2” NPT Outlet

- 650bs

- L– 36’’ W– 30’’ H– 75’’

Masterline (ML Series) is the most robust, heavy duty reciprocating air compressor lineup available. The perfect combination of quality components and efficient design make the ML Series rugged, affordable and smart. Because every model is built tough to last a lifetime in demanding working conditions, the ML Series is an outstanding alternative to splash-lubricated reciprocating compressors and small rotary compressors.

1. INTERCOOLER RELIEF VALVE – Prevents excessive pressure in the low pressure cylinder and intercooler, protecting pump and motor.

2. LOADLESS STARTING – With centrifugal, suction valve, or bleeder type unloader.

3. STAINLESS STEEL DISC AND SPRING VALVE ASSEMBLIES – Largest in the industry, ground and lapped to optical flatness for quiet and efficient operation.

4. DEEP FINNED CYLINDERS – Permit better cooling.

5. INTERCOOLER – Extra long with radiating fins located in the cyclone of air from the flywheel, providing maximum heat dissipation.

6. CAST IRON HIGH PRESSURE PISTONS – For durability and long life.

7. BALANCED FLYWHEEL – Provides effective air blast to cool compressor.

8. HEAVY DUTY CAST IRON CONNECTING RODS – Heaviest in the industry with replaceable rod bearings and pin bearings.

9. CAST IRON CRANKCASE – For strength and durability.

10. HEAVY DUTY DUCTILE IRON CRANKSHAFT – Ground and counter balanced with rifle-drilled oil flow ports.

11. OVERSIZED TAPERED MAIN ROLLER BEARINGS – Adjustable to assure long life with less friction.

12. PRESSURE LUBRICATION – With our centro-ring oiling system, pressurized oil is supplied internally through rifle-drilled crankshaft and rods to all bearings, bushings, and wearing surfaces for extended pump life.